Special Design For Fiber Opening Equipment - Smaro-New Auto Winder for Cotton Spinning – Yisun

Special Design For Fiber Opening Equipment - Smaro-New Auto Winder for Cotton Spinning – Yisun Detail:

BETTER

New type of anti-pattering mechanism

New type of the enclosed drum cover

New type of soft tension mechanism

Electronic anti-wrap drum

Drum optional freely

FASTER

Tension close loop control system

Optimized bobbin yarn suction nozzle

Optimized package yarn suction program

Optimized gill pin structure

Improved spindle panel installation method

MORE RELIABLE

New type of soft tension structure

Optimized tension yarn-catcher structure

Optimized empty bobbin conveyor

Increased empty bobbin selection box

Optimized air door structure

Transparent lints box window

Optimized mobile fan structure

Features

Uniform and consistent yarn tension, excellent building of yarn package

Optimized system structure to enhance production efficiency

Latest designed mechanical structure to reduce maintenance labor strength

Top level electronic yarn clearer, whole process control of yarn quality

Specifications

| Type | Single-spindles, single sided arrangement, left or right hand |

| Application | Nm 3.5 to the highest count cotton, wool synthetic yarn and blended single yarn |

| Winding speed | 400-2200m/min, step-less speed regulation |

| Number of winding spindles | 6 to 72 every two spacing increment |

| Spindle distance | 320mm |

| Applicable bobbin taper | 4°20, 5°57’ |

| Feeding bobbin | Diameter=32-65mm, length=180-300mm. |

| Joint type | Airsplicer, aquasplicer |

| Magazine type | 9 holes or 6 holes |

| Yarn clearer | The latest USTER/LOEPFE electronic yarn clearer. |

| Drum | DC motor coaxial transmission, step-less speed regulation |

| Circles on drum | 2 or 2.5 |

| Anti-pattering | Motor speed variation controlled in whole process. |

| Joints circle | Electrical logic control, intelligent cycle |

| Tension control | Electromagnetic pressure |

| Power installed | 33.57kw( actual consumption 11-15kw) |

| Overall dimension(60 spindles) | 22627x1365x2650mm |

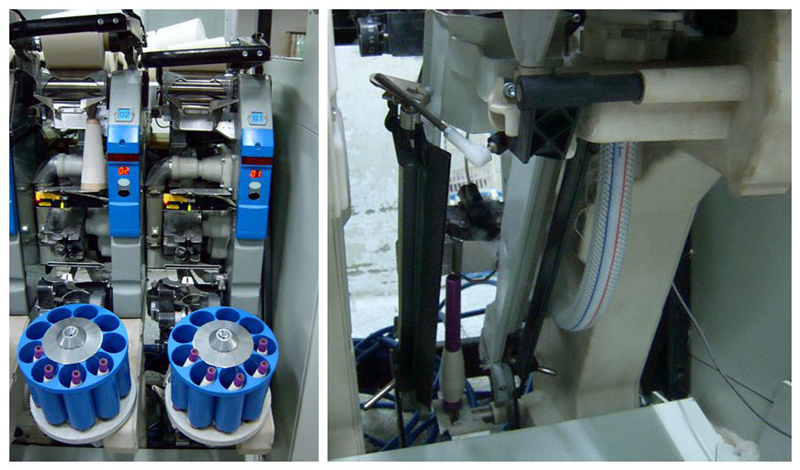

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for Special Design For Fiber Opening Equipment - Smaro-New Auto Winder for Cotton Spinning – Yisun , The product will supply to all over the world, such as: Durban, Bolivia, Luxembourg, Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.

Products categories

-

Phone

-

Top